|

|

|

|

|

Multi Spot Welder For Door Sash LH &

RH |

|

|

|

FEATURES :

- 100% linear motion thru

precision linear bearings.

- Low inertia moving parts

for quick follow-up.

- Adjustable electrode

force

1-15 kgs. (1-30 Kgs. optional).

- Weld initiation only

after achievement of preset electrode force.

- Universal electrode

setting.

- Available in Manual and

Pneumatic versions.

- Heads can be used for AC

or Capacitor Discharge Welding.

- Capacity – 1.5 & 3.0

KVA Short Circuit Current – 3500A/4500A.

|

|

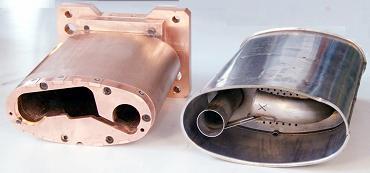

Twin Torch Synchronous Co2/MIG Rotory Welding SPM for

Exhaust Muffler Reer Assy. |

|

|

Twin Torch Synchronous Co2/MIG Rotory Welding SPM for

cat-con with side florges |

|

|

|

|

Dent Removing

Equipment |

LAP SEAM WELDER / SERIES LINE SEAM WELDER

|

|

Indexing

Type Multiprojection welder for Impeller Assy. (Stage-I & Stage

II)

( 8 ~ 10 Components per

minute)

Indexing

Type Multiprojection welder for Web & Rim Assg. Of brake shoe. (

6 ~ 8 Components per minute)

|

|